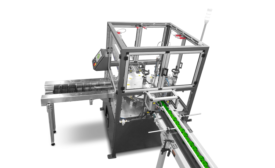

Cartoning

FBA Column

LCA Shows Balanced Environmental Results for Produce Container Systems

July 17, 2019

PMMI Column

To Protect and Serve

Packaging that ensures the safe arrival of online purchases drives protective packaging growth.

June 13, 2019

Fibre Box Association Column

Engineering Boxes for Relative Humidity in the Distribution Environment

March 20, 2019

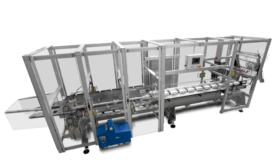

Spotlight Feature

2019 Packaging Outlook: The Future Is Now

Part 1 of 6: Consumer habits, new technology and machinery changes provide exciting opportunities, along with some challenges, for the packaging market.

March 12, 2019